We serve a diverse range of customers.

Kubota Brabender Technologie has over 60 years of experience in bulk material handling in a wide range of industries. We have acquired extensive expertise in our core markets such as plastic, food and pharmaceutical. In addition, Kubota Brabender Technologie solutions have successfully been implemented in a variety of industries including animal feed, detergents, glass, and construction materials. If there is a continuous process that requires accuracy you can expect a Brabender feeder to be installed.

Everything you need to know about food at Kubota Brabender Technologie can be found in our digital interactive brochure.

If you have questions regarding applications and it’s corresponding equipment, please feel free to contact us at info@kubota-bt.com.

Biopolymers

The use of biopolymers is an emerging trend. New compositions and properties are continuously being developed. Many different processes are used in their production depending on the additives. The feeding of natural fibers is particularly sensitive, and Kubota Brabender Technologie has developed special solutions for dealing with these fibers.

Recycling

The recycling of plastics has many challenging applications. The process includes shredding of moulded parts which produces a regrind that is very heterogeneous in shape and size when compared to virgin pellets. Kubota Brabender Technologie has a variety of feeder solutions for this difficult flowing regrind.

If you have questions regarding applications and it’s corresponding equipment, please feel free to contact us at info@kubota-bt.com.

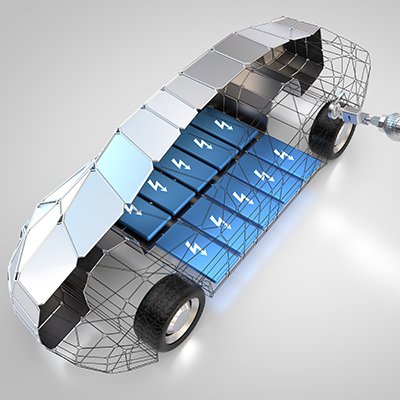

Battery Compounds

Whatever the cell type, the smallest unit of every lithium-ion cell consists of two electrodes and a separator, with the ion-conductive electrolyte between them. There are various methods and processes for manufacturing them. Kubota Brabender Technologie has feeding solutions that ensures dust control and explosion protection which are key safety considerations in battery production.

Detergent

The production of detergents and cleaning agents requires a very high capacity plant and a variety of different additives. Kubota Brabender Technologie’s large volume feeders featuring tare-compensated frames, blade screws up to 250 millimeters in diameter and hopper sizes up to three cubic meters in conjunction with our jet filters are specifically designed for high production capacities and output rates.

Copier Toners

Toners are typically manufactured using a batch process. The process can be add-weigh or loss-in-weight both with a moving collection hopper depending on accuracy requirements, batch size and batch time. Batch ingredients often include, wax, resin, metal powders, and pigments. Kubota Brabender Technologie has successfully implemented feeder solutions in many toner applications worldwide.

If you have questions regarding applications and it’s corresponding equipment, please feel free to contact us at info@kubota-bt.com.

Tablet Press

A tablet is more than compressed powder. It is made up of many ingredients, both active and non-active, often in different layers. These layers are often coated. For example, these coatings make a tablet easier to swallow or allow for a timed release of the active ingredient. Whatever the technology, it is absolutely essential to follow the formulation precisely, ensure a complete audit trail, adhere to the appropriate regulations and meet general manufacturing practices.

Other

Toothpaste for example, contains many different ingredients, such as abrasives, foaming agents, flavoring, aromas, colorants, other additives and active ingredients for prevention of tooth decay. These ingredients are processed in mixers, which must be fed in precise amounts by loss-in-weight feeders.

If you have questions regarding applications and it’s corresponding equipment, please feel free to contact us at info@kubota-bt.com.

Interested?

Contact us for a quick reply!

FLUX – Our customer magazine

Request the

current issue here.

Innovations, developments,

Case studies and much more.